Manufacturing (Food & Beverage)

with a Commercial UV Light Sanitizer

Our commercial UV light sanitizer minimizes contact time and additions to water or food, with no harmful by-products or changes to appearance or quality.

Utilizing a UV food sterilizer in your food or beverage manufacturing decreases the contact time utilized with other types of disinfection processes. Not only is it fast and effective, but it also cuts costs and is environmentally friendly.

UV Sterilizers have conventionally been used to treat water that is clean and fresh, but it can also be used to effectively disinfect not-so-clear water streams provided the UV equipment is sized appropriately to account for the difference in water qualit

Commercial UV Light Sanitizer for Water and Food Treatment:

The manufacturing market of food and beverage includes but is not limited to bottled water, food packaging, crop irrigation, carbonated beverages, product water for concentrates, soft drinks, tea, beer (microbrewers), wine, juice, vegetable wash water, meat, and poultry processing.

Many bottled water and soft drink producers around the globe rely on industrial UV food sterilizers to provide microbial-free, pure water and ingredients, which help protect the ‘brand’, and the flavor, and extend shelf life.

Manufacturing Resources

Aqua Ultraviolet has over four decades of experience in manufacturing commercial UV light sterilizers to provide custom solutions to a wide variety of applications.

Ultraviolet (UV) light is a form of light that is invisible to the human eye. It occupies the portion of the electromagnetic spectrum between x-rays and visible light. A unique characteristic of UV light is that a specific range of its wavelengths, those between 200 and 300 nanometers (billionths of a meter), are categorized as germicidal – meaning commercial UV light sanitizers are capable of inactivating microorganisms, such as bacteria, viruses, and protozoa.

Aqua Ultraviolet Manufacturing UV Systems

Aqua Ultraviolet (UV) Sterilizers System plays an important role in a complete water treatment process in food and beverage manufacturing.

Applications in Manufacturing of Commercial UV Light Sanitizer for Water & Food Treatment

- Disinfection – the most common application of UV Sterilization in water treatment. UV sterilization systems significantly reduce pathogen counts in incubation and rearing facilities and have proven to be the most cost-effective disinfection technology.

- TOC Reduction – in ultrapure water systems, UV treatment is used for the effective reduction of organics, commonly referred to as TOC.

- Chlorine/Chloramines Destruction – UV radiation can effectively eliminate residual chlorine/chloramine present in water.

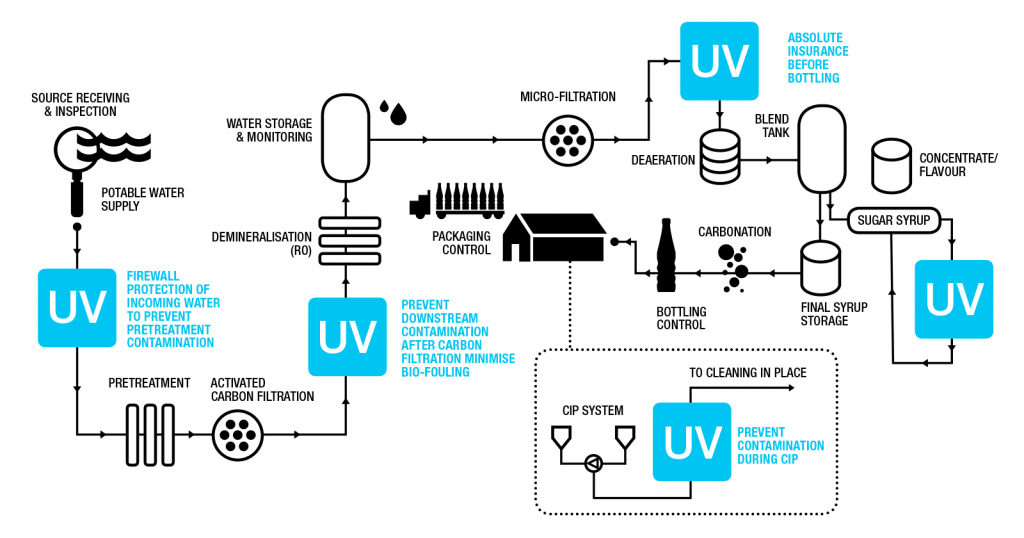

Typical UV Beverage Installation Schematic

Bottled water products are produced utilizing a multi-barrier approach, from source to finished product, that helps prevent possible harmful microorganisms or chemicals from contaminating the finished product or storage, production, and transportation equipment.

Effective use of UV located at strategic points in the process can protect the overall integrity of the end product, and lower maintenance costs by decreasing the microbial load.

It can also reduce some CIP sanitation frequencies and related maintenance on the equipment.

Have Questions About Commercial UV Light Sanitizers for Water & Food Treatment?

Contact us today via email or by phone at (800) 454-2725.